Quality

Demanding markets require the highest quality

Quality at Westwire Harnessing is achieved using the following key building blocks.

1 Quality Management Systems

Accreditation to industry recognised and assessed quality management systems.

BS EN ISO 9001:2015

AS9100 revision D

2 Build procedures

The use of time proven codes of practice for the procedures to build a harness in the correct manner that ensures consistency and quality across any type of harness that enters the shop floor. Each procedure in the construction of a harness from the cutting and stripping of base wires to over-braid and moulded shape installation is laid out in the codes of practice manual that operators are trained on and use in the production of a harness assembly.

3 Operator Training

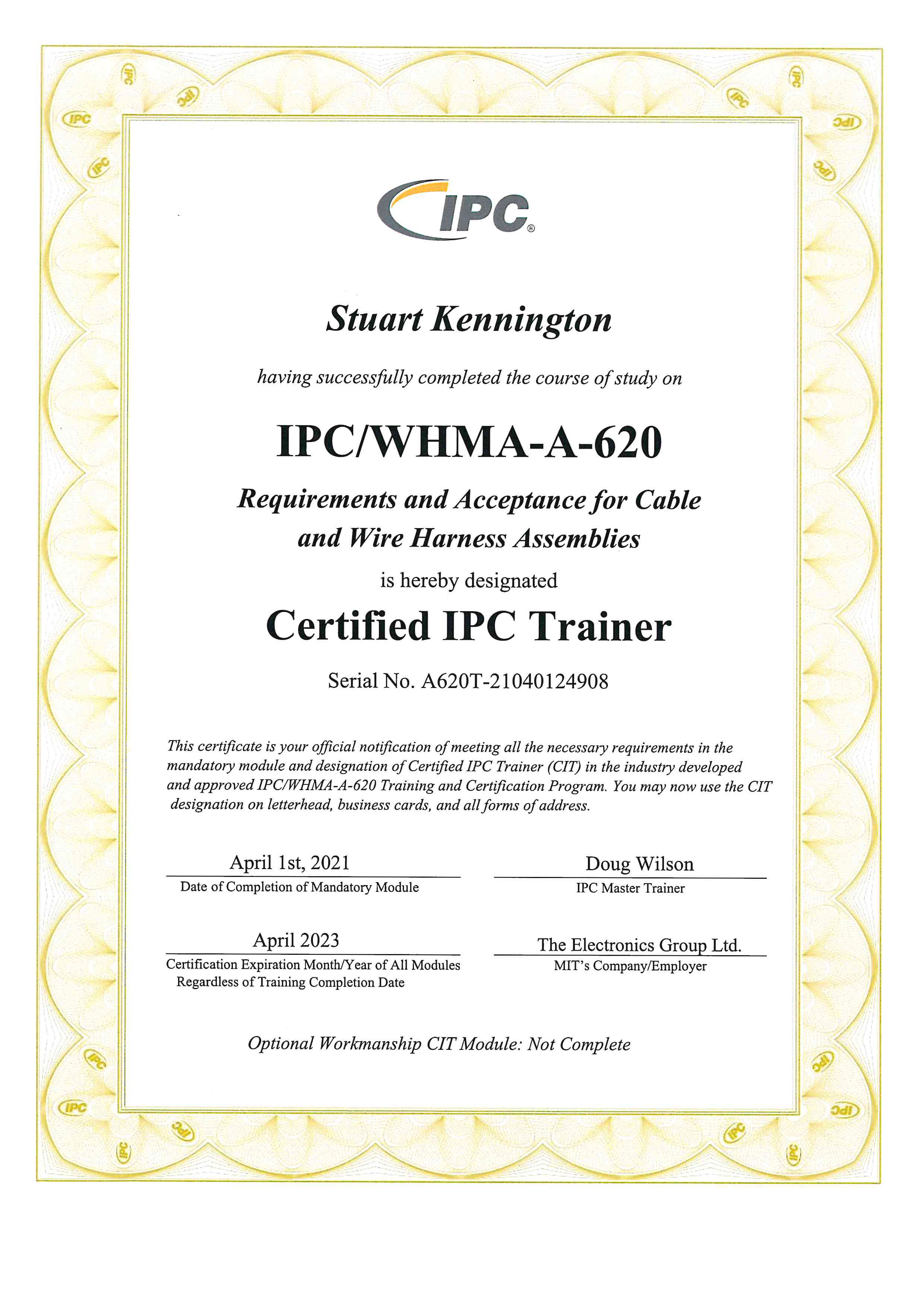

Operators are trained to the Westwire Harnessing Coded of Practice in conjunction with recognised training practices from the Internationally recognised IPC 620 programme. Westwire Harnessing has its in house IPC 620 trainers.

Operators have there own skills matrix that reflects their level of capability as they progress from basic levels to fully trained production operators.

4 Inspection & Test

In-production inspection and 100% final inspection and test are performed to ensure the final product meets the required relevant specification.

Fully automated electrical testing of cable assemblies is carried out using the MK Test Systems Automeg test equipment.

These systems allow us to test for;

Continuity, Insulation Resistance & High Voltage Insulation Break down.

This is all part of our full product traceability and conformance to national standards and ensure that Westwire Harnessing deliver a quality product.

Copies of test certification are available on request.

Additional Accreditations

· JOSCAR supplier accreditation registration

· RISQS Railway Industry Supplier Qualification Scheme

· IPC/WHM 620

· SC21 Signatory

· Various OEM Approvals

Manufacturing Procedures

· Manufacturing Codes of Practice (COP’S)

· Continuous Improvement through innovation and learning

· Lean Manufacturing

· 5S Housekeeping

· Prototype/First Article Inspection performed

· Visual Controls

· Performance Metrics

Certificates

AS9100D and ISO 9001:2015 - certificate

RISQS - certificate

JOSCAR - certificate

IPC Certificate

Cyber Essentials

WEAF

Armed Forces Covenant - Bronze Award