About us

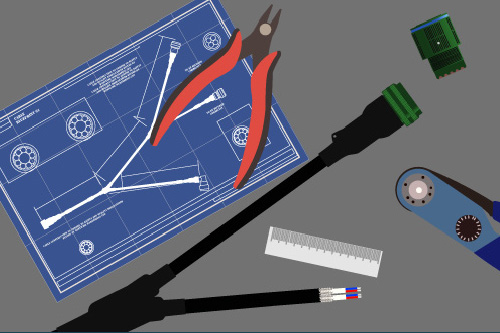

Specialists in the design and manufacture of military and rugged electrical interconnect systems.

Westwire Harnessing was founded in 1987 as a build to print harness maker working with the then novel new Raychem heat shrink technology they moved in to their first premises in 1989.

In the mid 90's Raychem Ltd used Westwire as one of the first approved harness shops to manage their military harnessing programs. During these years Westwire

grew its independence as a one stop shop for harness assemblies.

In 1999 Westwire opened an additional site in Cinderford to support a need for more local production on a significant vehicle programme.

With a need for more control over the design cycle Westwire increased its capability in to include harness design, thus being able to offer a complete service from concept, design, prototype, to production and in service MRO.

Today Westwire has consolidated its design and manufacturing to a 4000-sq ft purpose designed facility in Swindon.

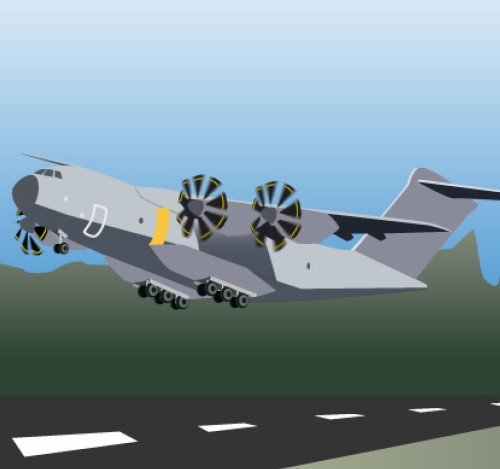

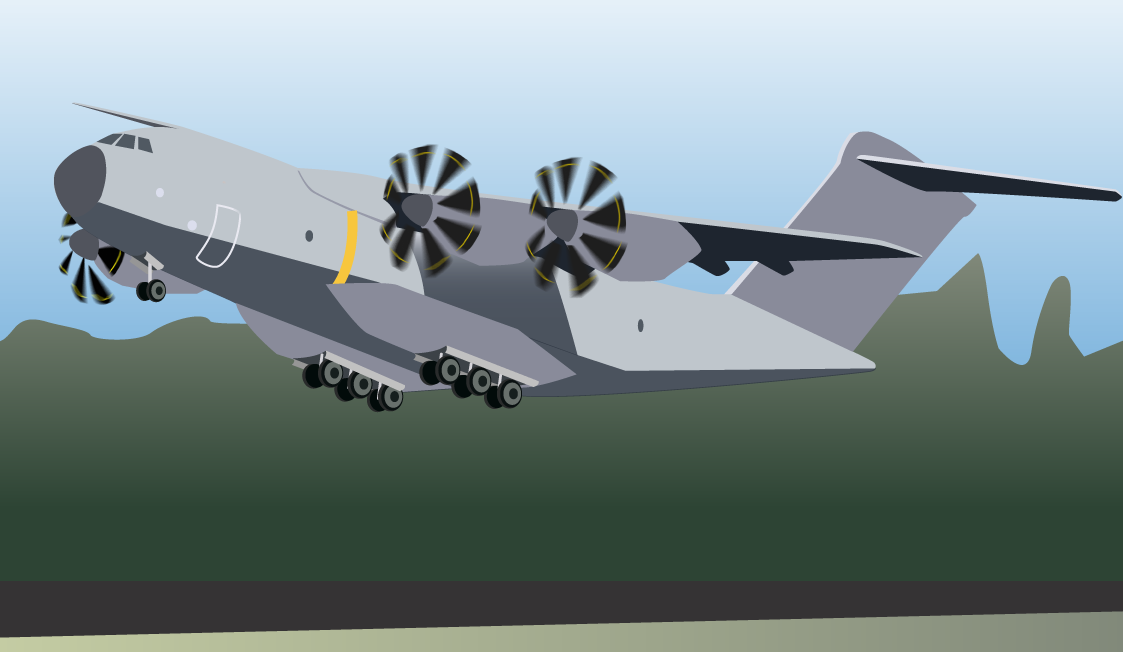

Westwire harnesses are used in a wide variety of applications. These range from military vehicles and equipment, aircraft, naval vessels to commercial transportation.

Westwire has now also started to supply a targeted selection of their own range of harness components. Please contact us for further details.

Westwire Harnessing - Connecting Your Future

Connecting Your Future

Supplying a quality product.

Demanding environments require exceptional products. These are brought about by utilising the highest quality components demanded by the relevant markets with years of proven track record in their performance, combined with excellence in Design, Manufacture, Test, Quality and After Sales Support.

Harsh Environments

Material Choice

There is no one solution fits all in the wire and harnessing world.

Material choice is dictated by platfrom type and performance requirement within the platform. Military vehicles are driven by aggressive fluid resistance, temperature and robustness. Naval applications key requirement are Low Smoke and Zero toxicity generation, although we are seeing some requests for LSZ in the crew compartments for vehicles now. Aircarft are mostly driven by weight hence the open loom technologies that are used.

For these reasons its important to discuss your needs with those that can support with their expertise.

RF Solutions

British Army Vehicle RF cable solutions

Key to Success

Having an experienced team of cable designers, builders and tester and working with a supportive supply chain allows Westwire to supply quality products in acceptable lead times.